QA/QC Documentation

It is normal for the Customer to specify how and in what format the QA/QC Turnover Dossiers are to be presented. This is normally given to the supplier in the form of a Project Procedure documentation.

QA/QC Documentation Retention

It is normal for Project QA/QC documentation to be retained by the supplier or contractor for a minimum period of five years.

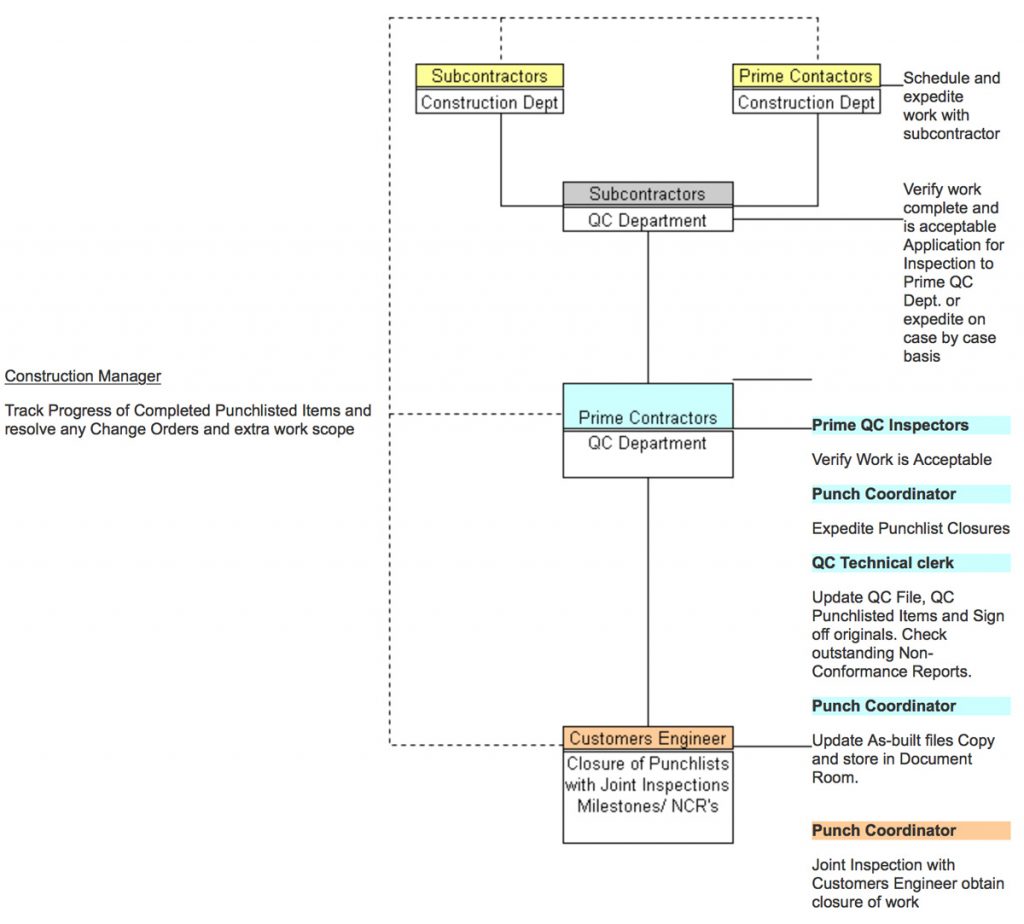

Punch Listed Items

Prior to the completion of a Project Milestone all punchlisted items should be identified and coordinated through one point of source.Punchlisted items should be agreed and coordinated with the customer prior to final handover.

Customers Warranty Claims

In such cases were there is a failure of the product, the QA/QC Turnover Dossiers will be able to identify whether there is a product manufacturing defect or if it was an installation construction failure.